The Total Solution for Process Water Recycling

EPA Recognized Water Systems

Four Decades of Water Treatment Solutions

Since 1986, Separation Technologists has pioneered environmental technology for manufacturing and parts cleaning industries. With over 700 systems implemented worldwide, we deliver closed-loop wastewater solutions that significantly reduce the costs of essential manufacturing resources—water and chemicals your business uses daily.

The Complete Solution for Process Water Management

- EPA-Recognized Technology. Our systems are built on proven methodologies recognized by environmental regulators for their effectiveness and compliance.

- Environmental Stewardship. We design solutions that not only meet current regulations but anticipate future environmental standards.

- Turnkey Implementation.From initial consultation through installation and ongoing support, we handle every aspect of your water treatment project.

Measurable Results for Forward-Thinking Manufacturers

Our innovative closed-loop wastewater solutions deliver significant reductions in operating costs by minimizing:

- Fresh water consumption

- Chemical usage

- Waste treatment expenses

- Regulatory compliance costs

- Production interruptions

We transform water management from an operational burden into a competitive advantage, allowing you to redirect resources toward your core business while reducing your environmental footprint.

Carbon & DI Portable Tank Exchange

Ship your spent media tanks to us and we return them cleaned and filled and ready for service.

Closed Loop & Wastewater Treatment

Turnkey treatment systems let you removing metals prior to discharge or return clean DI water to your process.

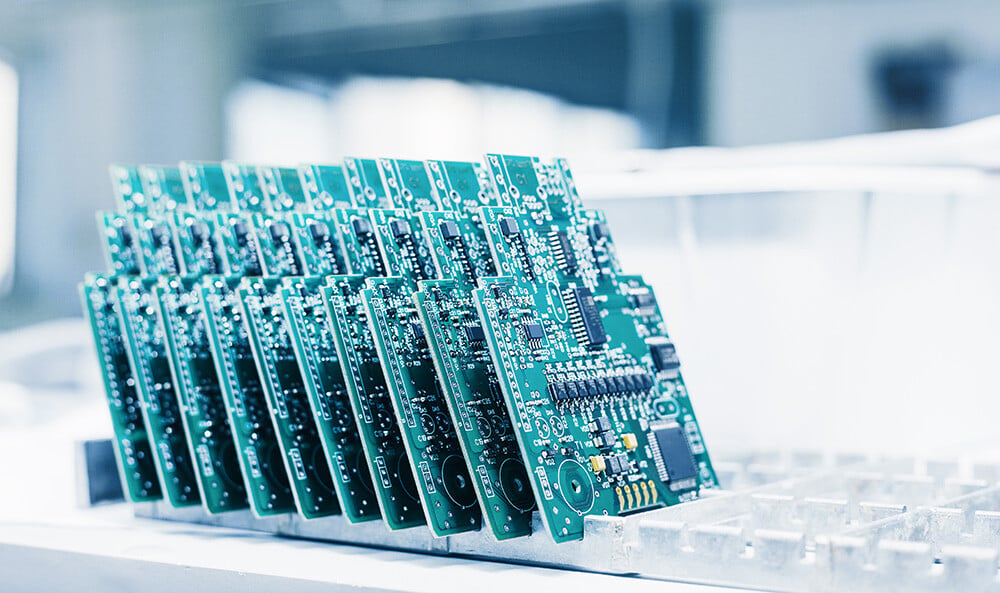

Supporting the PCB & Semiconductor Industry

Premium quality virgin, semiconductor-grade media for ultrapure applications. Click below to learn more about the markets we serve.

In defense manufacturing, the performance and reliability of military systems depend on precision. Deionized (DI) water ensures that components like radar systems, avionics, and military electronics remain free of contaminants that could affect their function and durability.

Key Applications of DI Water

-

Cooling Systems: prevent overheating in military electronics without causing electrical damage.

-

Cleaning Components: Removing contaminants from sensitive military equipment like circuit boards and sensors.

-

Electroplating: Ensuring that metal coatings are evenly applied to key components, enhancing durability.

-

Surface Treatment: Rinsing parts after chemical treatments, ensuring no residue remains that could affect performance.

How DI Water is Used in Defense Manufacturing

DI water absorbs contaminants over time, so it needs to be filtered and replaced regularly. Recycling systems help maintain water quality and reduce costs by reusing DI water for cleaning and cooling, minimizing waste and lowering operational expenses.

Deionized (DI) water is crucial in electronics manufacturing, where purity is essential. Used in cleaning, rinsing, cooling, and testing, DI water ensures that components like semiconductors and printed circuit boards (PCBs) remain free from contaminants that could affect performance.

Key Applications of DI Water

-

Cleaning & Rinsing: Removes residues from PCBs and semiconductors.

-

Semiconductor Fabrication: Ensures pristine wafer surfaces for microcircuit creation.

-

Cooling Systems: Safely cools electronics without the risk of electrical damage.

-

Electroplating: Ensures smooth metal layer application and rinses off chemicals post-process.

What Happens to DI Water During Manufacturing?

As DI water interacts with components, it absorbs contaminants, requiring filtration or replacement. Recycling systems allow for reuse, reducing waste and operational costs.

In pharmaceuticals and biotechnology, purity is critical. Deionized (DI) water ensures the highest standards of quality by preventing contamination in drug production, laboratory testing, and formulation. DI water meets regulatory standards like GMP and USP, ensuring the safety and efficacy of products.

Key Applications of DI Water

-

Drug Production: DI water is used in creating solutions, suspensions, and injectable drugs.

-

Sterile Preparation: Used for cleaning equipment and ensuring sterility in production environments.

-

Laboratory Testing: Essential for R&D and quality control to prevent contamination.

-

Biotechnology: DI water supports cell culture preparation, media, and buffer solutions.

-

Cleaning: Used to sanitize facilities, equipment, and instruments.

How DI Water is Used in Pharmaceutical Production

As DI water is used, it absorbs contaminants like dust, bacteria, and ions. Closed-loop filtration systems help recycle and purify DI water, ensuring consistent quality and reducing waste. Regular testing ensures that water meets strict quality standards and prevents microbial contamination.

In semiconductor manufacturing, even the smallest impurities can ruin delicate components like microchips. Deionized (DI) water is vital for cleaning, rinsing, and etching wafers to maintain high purity and prevent defects in the production process.

Key Applications of DI Water

-

Wafer Cleaning & Etching: DI water removes microscopic contaminants to ensure clean, functional chips.

-

Deposition Processes: After chemical vapor deposition (CVD) or physical vapor deposition (PVD), DI water rinses the wafers to remove harmful residues.

-

Cooling Systems: DI water in cooling systems prevents scaling and ensures efficient temperature control during production.

Why DI Water Matters

-

Eliminating Contaminants: DI water removes impurities that can affect the functionality of semiconductor components.

-

Meeting Industry Standards: High-quality DI water is crucial for adhering to strict industry standards and environmental regulations.

In medical device manufacturing, DI water is essential for maintaining cleanliness, sterility, and precision. It ensures that components, equipment, and the production environment remain free from contaminants that could compromise patient safety.

Key Applications of DI Water

-

Cleaning & Rinsing: DI water cleans components, removing residues, oils, and impurities without leaving harmful traces.

-

Sterilization: DI water is used in sterilization and disinfection processes, including in autoclaves, to ensure devices like surgical tools and implants are free of microbial contaminants.

-

Surface Preparation: For devices requiring coatings, DI water ensures that no residues interfere with the coating's effectiveness.

Why DI Water is Essential

-

Product Safety: DI water ensures medical devices are free from contaminants, protecting patient health.

-

Regulatory Compliance: It helps meet strict standards like FDA GMP and ISO 13485 for manufacturing purity and safety.

-

Precision Manufacturing: DI water supports high-precision cleaning of devices like pacemakers and implants.

In metals fabrication and plating, the quality of water directly impacts the final product. Deionized (DI) water ensures surfaces are clean, free from contaminants, and ready for precise processes like electroplating and anodizing. It maintains high standards of quality, consistency, and performance while also supporting sustainability through recycling.

Key Applications of DI Water

-

Surface Cleaning: DI water removes oils, dust, and residues from metal surfaces before plating or coating.

-

Electroplating & Coating: DI water is used to rinse metals after plating to ensure uniform coating and prevent contamination.

-

Anodizing & Surface Treatment: Essential for rinsing metals post-anodizing to ensure a flawless finish.

-

Cooling Systems: Prevents corrosion and scale in high-heat fabrication processes like welding and casting.

-

Etching & Milling: DI water removes chemicals and residues after etching to maintain metal quality. DI water is used in creating solutions, suspensions, and injectable drugs.

Managing DI Water During Metal Fabrication

As DI water is used, it collects contaminants like oils, dust, and chemicals. Closed-loop filtration systems recycle and purify water for reuse, reducing waste and improving sustainability. Regular maintenance ensures water quality remains optimal.

Ready to revolutionize your approach to process water?

Reach out today for a consultation tailored to your specific operational challenges.